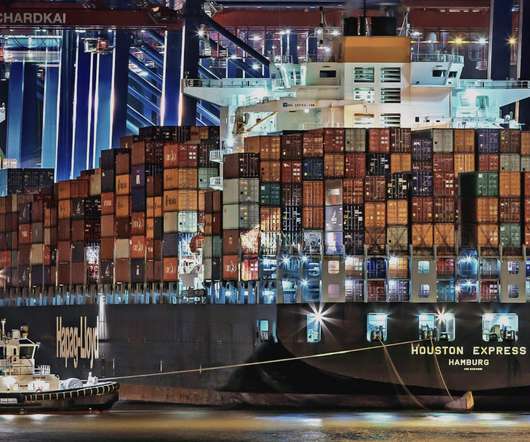

Better Inventory Management Requires International Suppliers To Step Up to Digital Transformation and Collaboration

Logistics Viewpoints

AUGUST 9, 2022

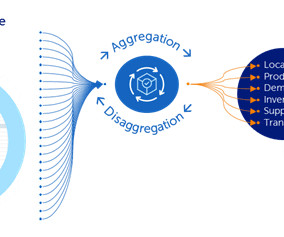

As I’ve underscored here before , more and better data, along with pervasive data sharing across the supply chain ecosystem, turbo-charges opportunities for collaboration and problem-solving. Matt Elenjickal is the Founder and Chief Executive Officer of FourKites. He lives in Chicago.

Let's personalize your content