International Logistics: Deep Integration and Practice of RPA Technology

Logistics Viewpoints

FEBRUARY 19, 2025

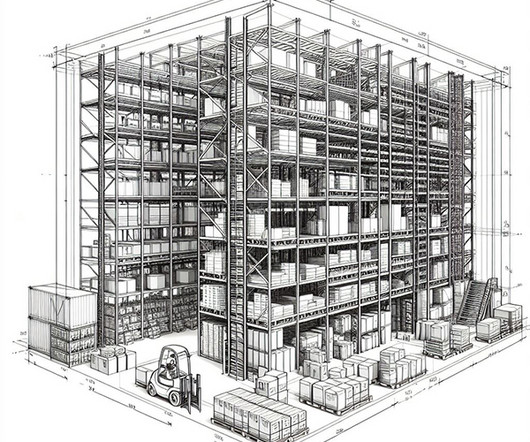

With the development of the digital wave, Robotic Process Automation (RPA) technology has gradually emerged as an important tool in the international logistics industry. It significantly improves the efficiency and accuracy of business processes while reducing the error and cost of manual operations.

Let's personalize your content