Infor Analyst Innovation Summit 2025: A Look at the Future of Industry Cloud

Logistics Viewpoints

MAY 1, 2025

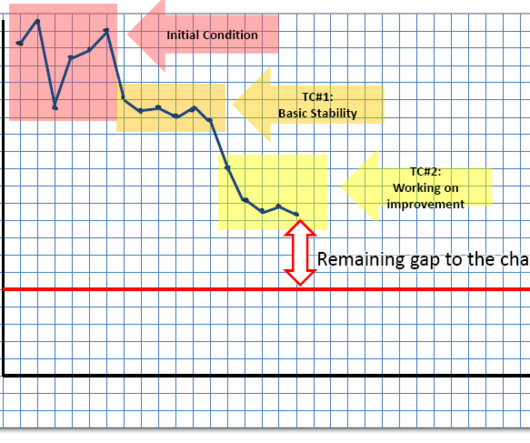

Together, they presented the vision for the future and innovation priorities. A customer case story presented showed significant speed improvements in identifying process issues and reductions in employee time spent on this task, potentially leading to substantial annual savings through improved early payment discounts.

Let's personalize your content