Cost To Serve – A Smarter Way to Improved Supply Chain Profitability

Logistics Bureau

NOVEMBER 14, 2018

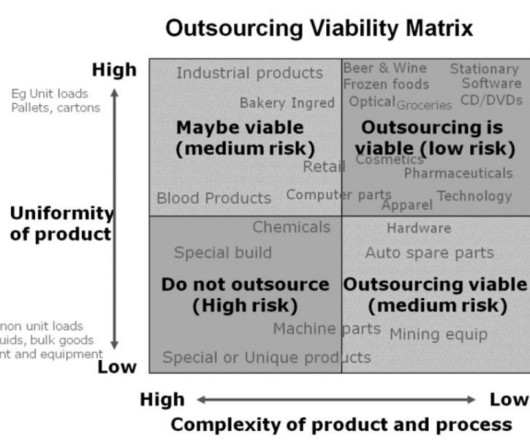

Too much leads to resources being monopolised on gathering tons of data and a subsequent risk of “paralysis by analysis” Cost to Serve (CTS) is an approach that helps you avoid both extremes. Besides optimising the present or fixing the past, CTS reporting and analysis opens the door to what-if scenarios and projections.

Let's personalize your content