Amazon and the Shift to AI-Driven Supply Chain Planning

Logistics Viewpoints

MARCH 26, 2025

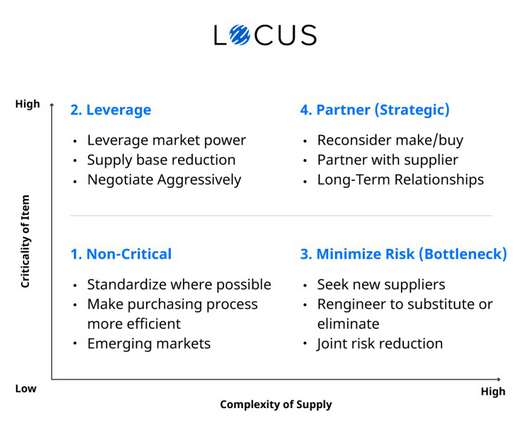

Limitations of Traditional Supply Chain Planning Traditional supply chain planning relies on retrospective analysis. AI-driven procurement tools analyze pricing trends and supplier performance to negotiate better contract terms. AI enhances supplier coordination by aligning raw material procurement with production needs.

Let's personalize your content