Autonomous Devices for Digital Warehousing

SIPMM Professional Publications

APRIL 18, 2019

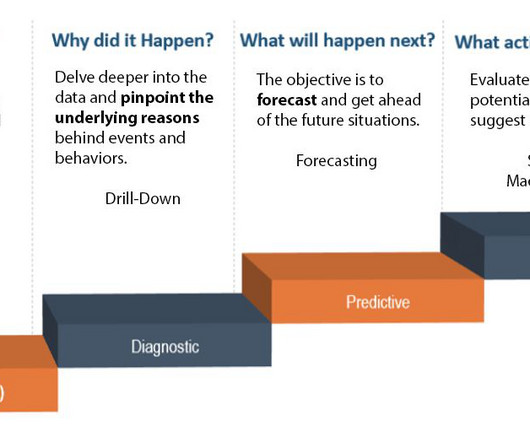

New technologies and tools are coming up to meet our needs. A digital data warehouse is designed with the purpose of improving business decisions by allowing data consolidation, analysis, and reporting at different aggregate levels. The post Autonomous Devices for Digital Warehousing appeared first on SIPMM INSTITUTE.

Let's personalize your content