Enterprise shippers’ top 6 logistics strategies to know

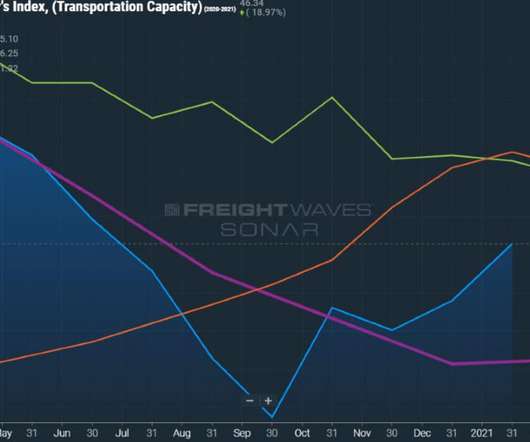

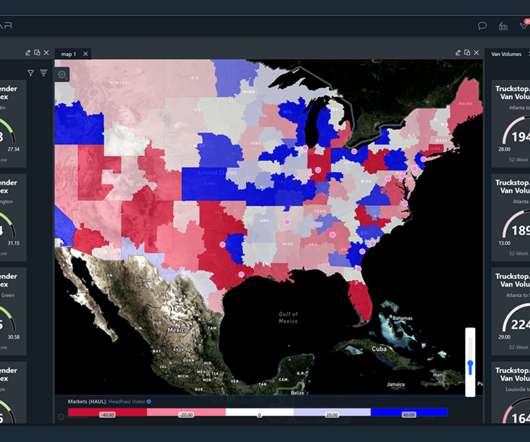

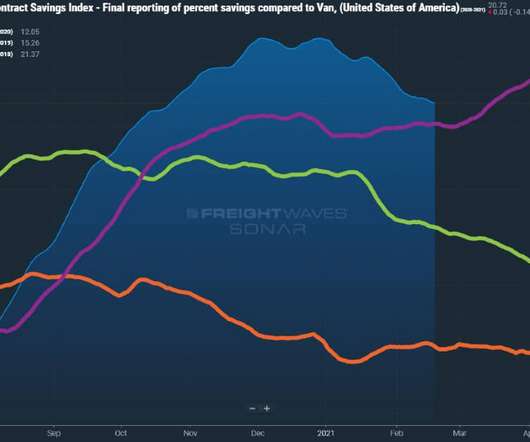

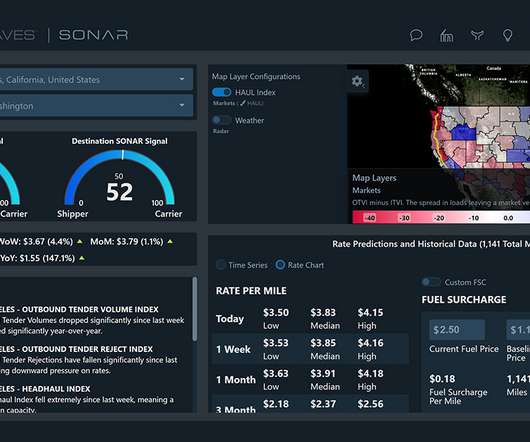

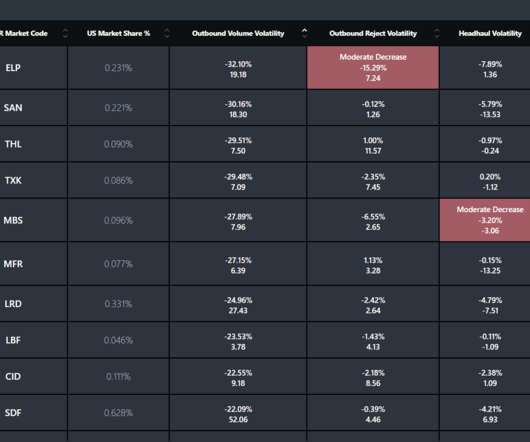

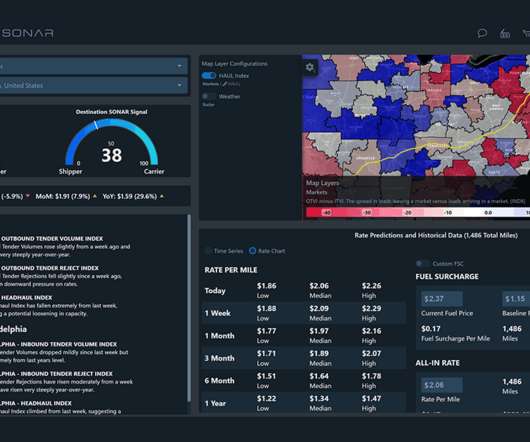

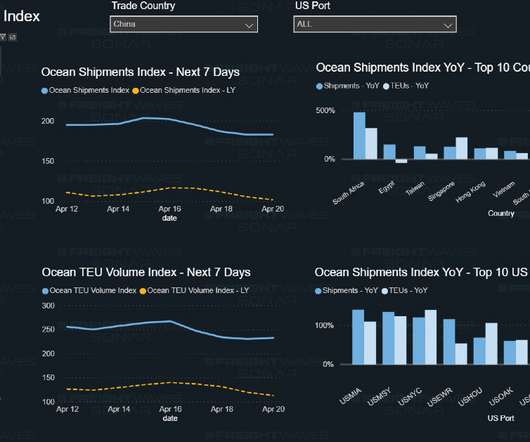

FreightWaves SONAR

JANUARY 28, 2021

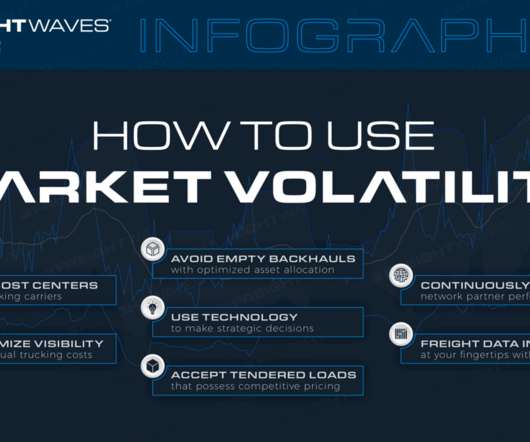

Adjusting current logistics strategies demonstrated the second great challenge of the pandemic. Embracing new and improved logistics strategies remains the best way to adapt to clients’ changing demands in 2021 and beyond. Strong and versatile logistics strategies depend on this data. Download the White Paper.

Let's personalize your content