Strategies for E-Commerce Success: Optimizing Parcel Spend

Stord

JULY 1, 2024

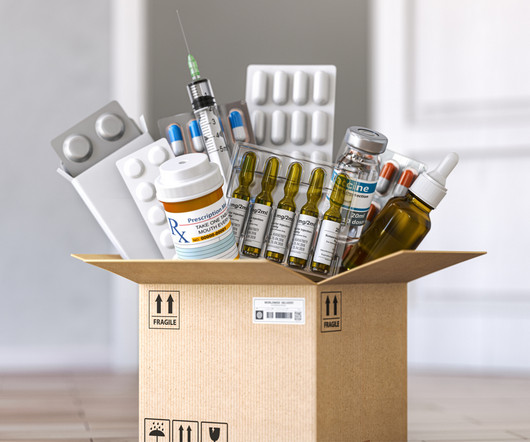

Every step of the process that brings your product from creation to your consumers’ front-door can cut into those margins and reduce your profitability. Understanding Parcel Expense Factors Before we explore ways to save, let's make sure we understand why parcel is such a massive expense for e-commerce brands.

Let's personalize your content