If There’s a Manufacturing Skills Gap, How Do We Close It? 4 Ways to Combat the Gap

GlobalTranz

OCTOBER 12, 2016

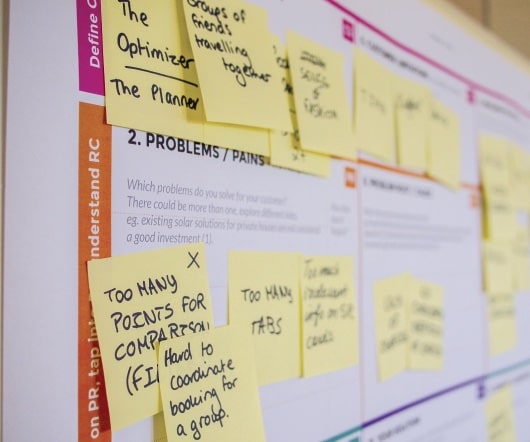

The manufacturing skills gap, which we first defined here , is a real threat to the future of the U.S. More skilled workers are retiring than ever before, up to 10,000 baby boomers daily. However, manufacturers can work to reduce the overall manufacturing skills gap by following these four steps. Invest in STEM Education.

Let's personalize your content