Toyota Kata: What If There Is No Takt Time?

The Lean Thinker

APRIL 20, 2020

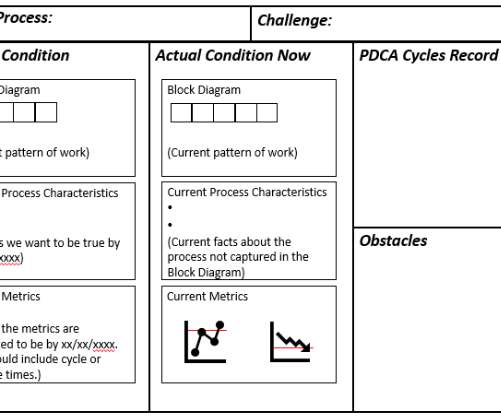

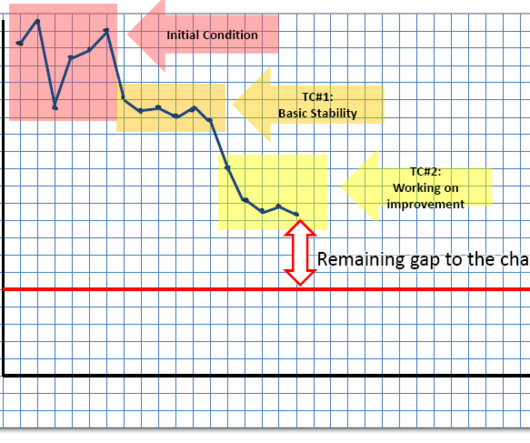

Steve’s proposal was a Current / Target condition template that includes more than the “blank generic version” but doesn’t focus so much on the cadence and timing: From Steve Medlin’s KataCon presentation. From an industrial engineering standpoint, takt time is an expression of how much capacity you need.

Let's personalize your content