Context. The Key to Unlocking the Power of Your Supply Chain Data Strategy

Logistics Viewpoints

NOVEMBER 26, 2024

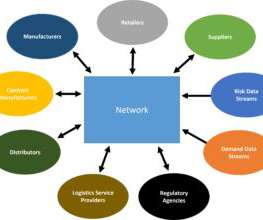

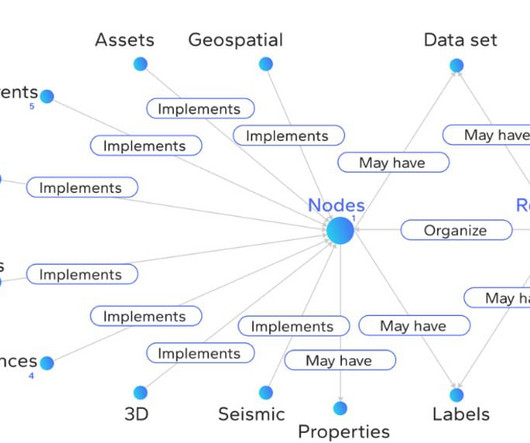

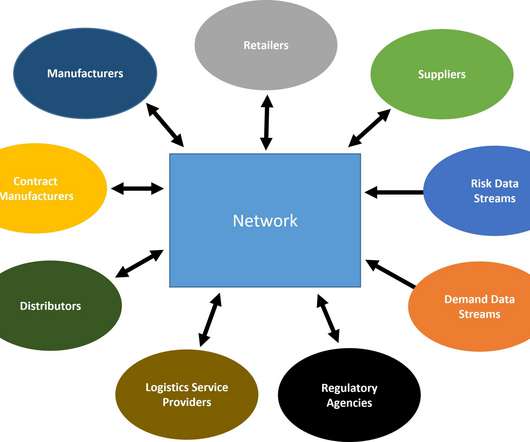

Our daily lives are inundated with data. Supply chain teams face a similar dilemma – companies are overloaded with vast amounts of data, and the ability to sift through the noise and focus on relevant insights has become a critical capability. Why Context Matters Context transforms data into actionable insights.

Let's personalize your content