The New Generation of Microservices-Based Applications Can Create ‘Cliff Events’

Logistics Viewpoints

AUGUST 26, 2024

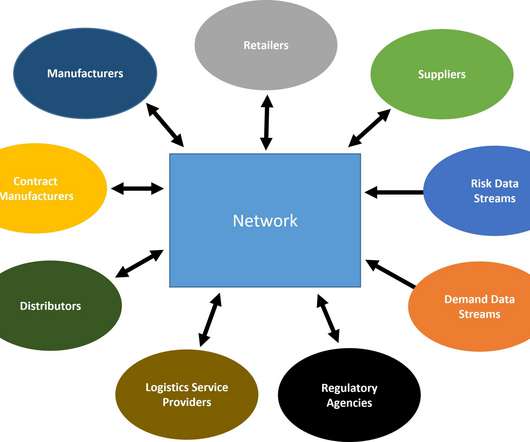

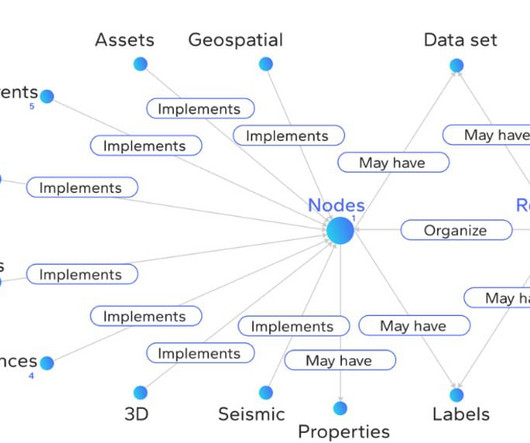

Executives at Blue Yonder refer to this as a “cliff event.” To avoid a cliff event, Blue Yonder has proceeded by turning its supply chain applications into applications that are part traditional software code and part microservices. Blue Yonder, for example, has created a microservice for transportation optimization.

Let's personalize your content