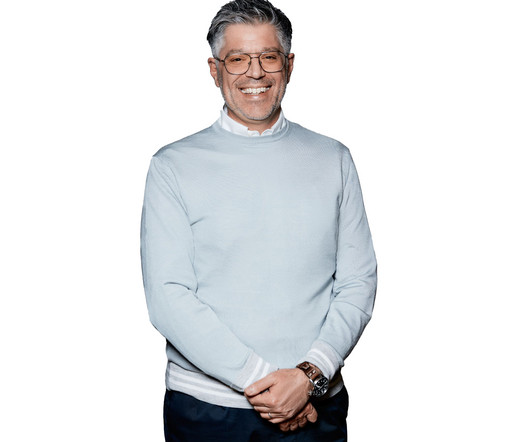

Supply Chain Shock Waves: Strategies for Survival and Success with Mark Baxa and John Delgado

The Logistics of Logistics

MARCH 21, 2025

Mark Baxa , John Delgado and Joe Lynch discuss supply chain shock waves: strategies for survival and success. Louis University Center for Supply Chain Excellence Global Supply Chain Certificate Programs and has taught executive courses. He also co-leads the St.

Let's personalize your content