Octillion Reaches Milestone Distributing 1,500 Battery Packs Per Day Globally

NGT News

DECEMBER 9, 2021

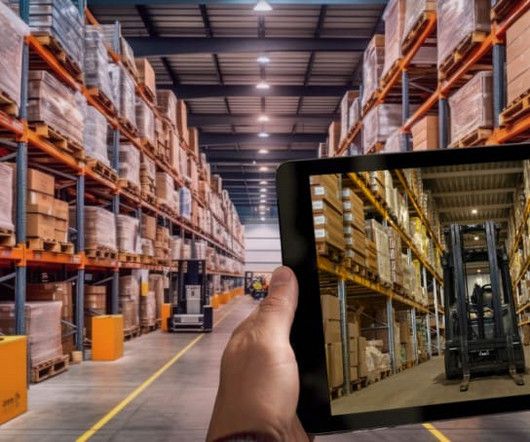

Octillion Energy, a global supplier of advanced high-density lithium-ion battery packs for passenger cars, trucks, buses and energy-storage systems, has achieved the milestone of shipping over 1,500 battery packs a day and expects to hit 2,000 packs per day this month.

Let's personalize your content