Bigging up Data Analytics

Logistics Business Magazine

MARCH 24, 2021

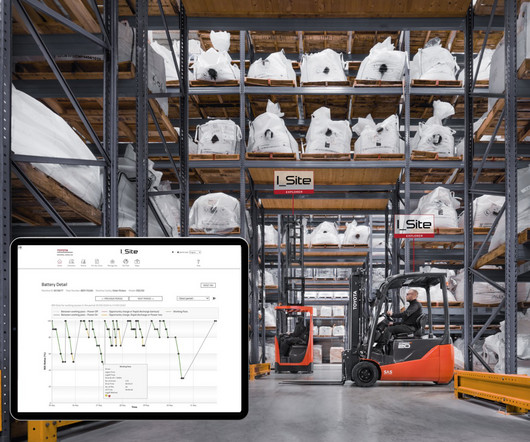

Big data presents supply chain and warehouse managers with an unprecedented opportunity to acquire real-time visibility of goods in transit and part of inventory, writes Tony Dobson -SnapFulfil CEO. There’s plethora of data in the warehouse now, with lots of dashboards to present the figures, but information overload is happening.

Let's personalize your content