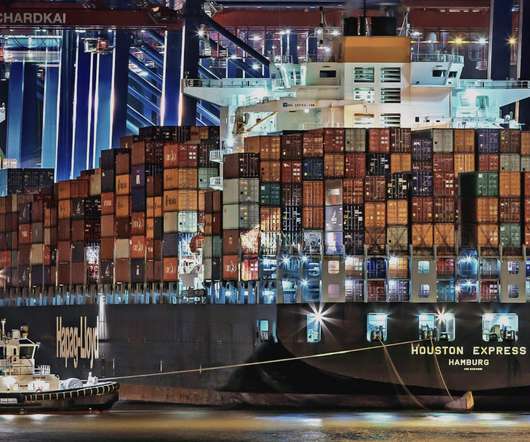

4 tips to reduce cargo damage and save money on shipping costs

Shipping and Freight Resource

JUNE 29, 2020

But if you can reduce cargo and shipping damage , you can cut shipping costs. Other departments of your organization will also save money and function more efficiently, too. With the right packaging, strategy, and tools, you can cut shipping costs by as much as 60%. Choose Packaging and Pallets Carefully. Fill Containers Wisely.

Let's personalize your content