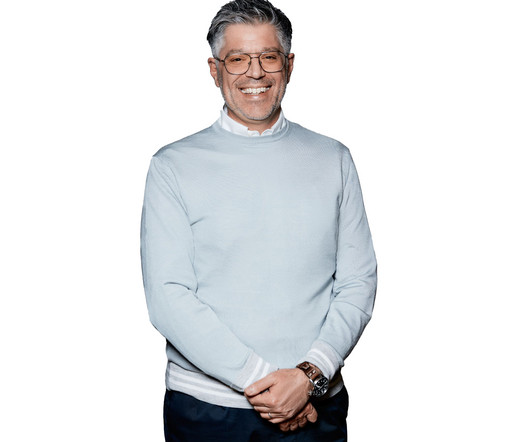

Thriving in an Omnichannel World with Akash Gupta

The Logistics of Logistics

OCTOBER 2, 2023

The company’s robots are used to pick, pack, and sort items in warehouses and fulfillment centers. solution combines aggregated market data and customer data with advanced machine learning techniques to deliver short-term predictive freight market pricing specific to a company’s individual buy and sell behavior.

Let's personalize your content