Protect your Customers and Orders with Data

Stord

OCTOBER 15, 2024

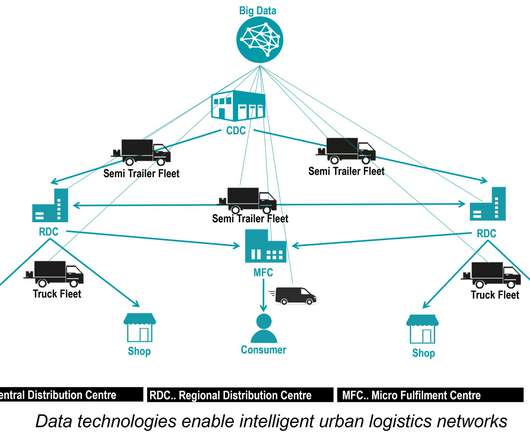

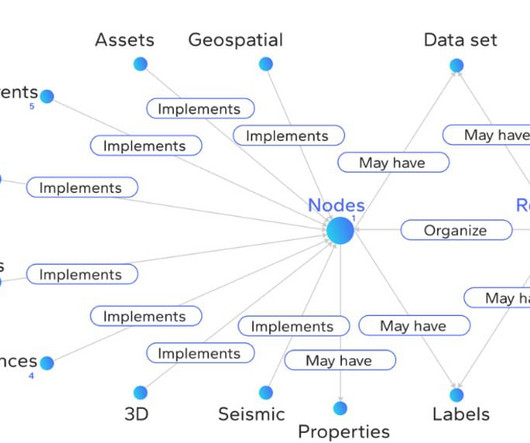

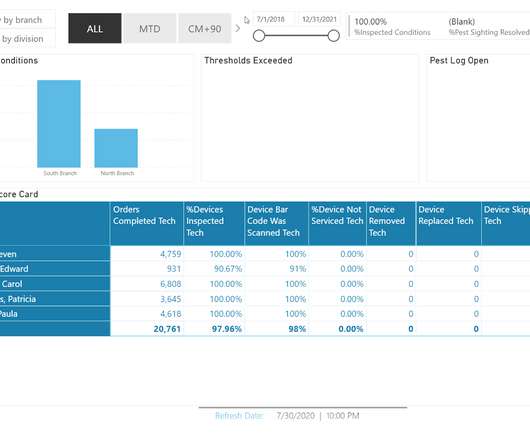

In this competitive market, protecting your customers, and their orders, is critical to your brand's longevity. But how do you do this for every order, each and every day, forever? And how do you pick the right carrier if you are now receiving new data of damaged packages? It all comes down to how well you can utilize your data.

Let's personalize your content