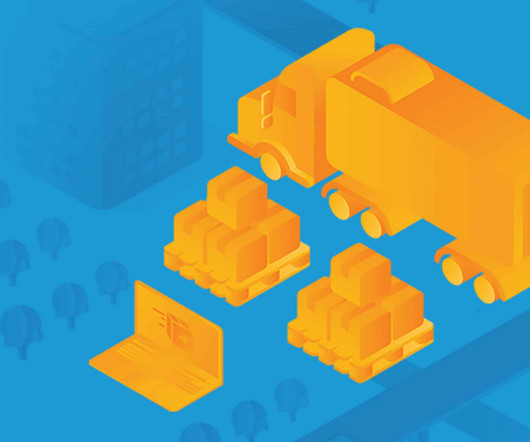

World’s Fifth Fastest Growing Retailer Automates Replenishment Planning

Logistics Viewpoints

FEBRUARY 1, 2021

Supporting Growth Requires Automated Replenishment Planning. lu asserts, would not have been possible or profitable without automated replenishment. “To To support this massive speed, we needed a solid replenishment solution in place.” The company’s supply chain planning and automated replenishment solution comes from Solvoyo.

Let's personalize your content