[INFOGRAPHIC] The Evolution and History of Supply Chain Management

GlobalTranz

JANUARY 23, 2015

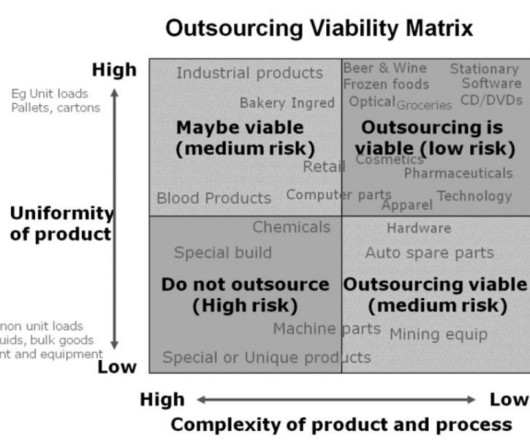

The “unit load” concept gained popularity and the use of pallets became widespread. The computerization of this data opened the door to a huge opportunity for innovations in logistics planning, from randomized storage in warehouses to optimization of inventory and truck routing.

Let's personalize your content