What Shippers and Retailers Need to Know for Peak Season Planning 2022

The Logistics of Logistics

JUNE 23, 2022

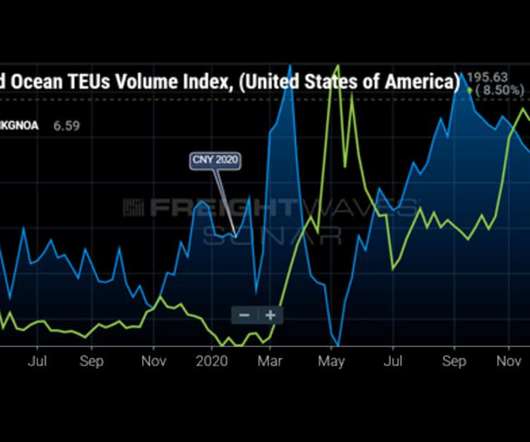

What Shippers and Retailers Need to Know for Peak Season Planning 2022. Original Article: What Shippers and Retailers Need to Know for Peak Season Planning 2022. We’ve seen how the lockdowns in Shanghai snarled global supply chains. WRITTEN BY STEFANY MARTIN / POSTED ON JUNE 9, 2022. Weather events might also be factors.

Let's personalize your content