Navigating Today’s Tariff Turbulence with Cloud Technology

Logistics Viewpoints

MAY 20, 2025

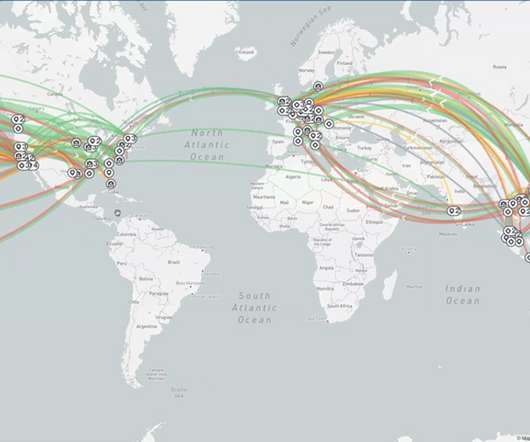

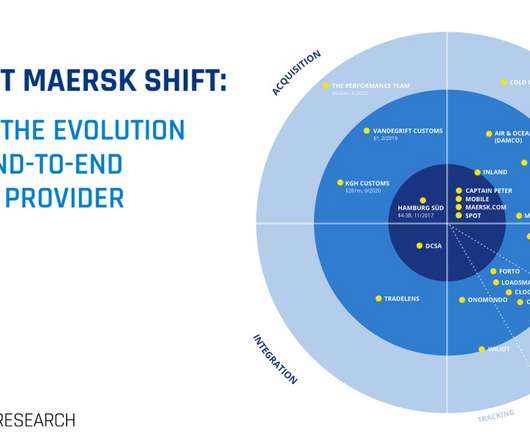

The rapid implementation and modification of tariffs, often announced through social media even before formal policy announcements, have created unprecedented challenges for global supply chains. Technology: The Critical Adaptation Tool The current tariff volatility has exposed the limitations of legacy systems and manual processes.

Let's personalize your content