What is Order Picking?

Logistics Bureau

NOVEMBER 26, 2024

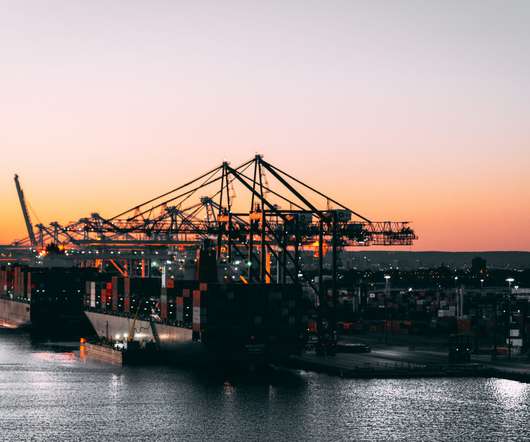

Order Picking is the productive operation in a warehouse operation. Any warehouse design exercise that doesn’t include a rigorous approach to designing the processes and equipment layout for Order Picking, is suspect. Reducing the operator travel is achieved by pick-face design, using specialised equipment, (e.g.

Let's personalize your content