Unmasking the Supply Chain: How Blockchain Brings Transparency and Trust

Logistics Viewpoints

FEBRUARY 26, 2025

ERP & SCM Systems (2000s2015): Centralized ERP suites (e.g.,

This site uses cookies to improve your experience. To help us insure we adhere to various privacy regulations, please select your country/region of residence. If you do not select a country, we will assume you are from the United States. Select your Cookie Settings or view our Privacy Policy and Terms of Use.

Cookies and similar technologies are used on this website for proper function of the website, for tracking performance analytics and for marketing purposes. We and some of our third-party providers may use cookie data for various purposes. Please review the cookie settings below and choose your preference.

Used for the proper function of the website

Used for monitoring website traffic and interactions

Cookies and similar technologies are used on this website for proper function of the website, for tracking performance analytics and for marketing purposes. We and some of our third-party providers may use cookie data for various purposes. Please review the cookie settings below and choose your preference.

Logistics Viewpoints

FEBRUARY 26, 2025

ERP & SCM Systems (2000s2015): Centralized ERP suites (e.g.,

Logistics Business Magazine

JANUARY 17, 2022

Brady Corporation presents a new, highly reliable dual-frequency RFID label that combines the advantages of UHF and NFC RFID technology. Track, trace, and engage with almost any item or product via a single, reliable and industrial-grade label with dual frequency UHF and NFC RFID technology.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

How to Modernize Manufacturing Without Losing Control

A Roadmap For Modernization: How To Break Free From Your Monolith Before July 31, 2026

Logistics Business Magazine

JANUARY 13, 2023

OPEX® Corporation, a global leader in next generation automation for almost 50 years, is expanding the capabilities of its leading-edge ‘Sure Sort® Warehouse Automation’ technology to incorporate radio frequency identification (RFID) scanning to meet client needs and increase operational speed and efficiency. About OPEX.

Logistics Viewpoints

MARCH 12, 2025

Today, logistics firms rely on RFID tags, barcode scanning, and centralized tracking systems, which are vulnerable to tampering and inefficiencies. Cross-Border Trade & Customs Compliance International trade involves lengthy customs clearance, regulatory approvals, and documentation.

Logistics Viewpoints

MAY 1, 2025

IDP converts paper-based documents into automated digital processes. The platform leverages AI and Digital Technologies like RFID at Source (reducing receiving and packing time and chargebacks) and 2D barcodes/Digital Links to drive transparency and capture data for product circularity. RPA automates manual and repetitive tasks.

Logistics Viewpoints

APRIL 14, 2025

Outcomes: Higher order accuracy and improved on-time performance Lower labor cost per unit moved and less reliance on overtime Reduced downtime due to more proactive equipment servicing Many of these tools depend on inputs from sensors such as RFID tags, barcode scans, and environmental monitors.

3PL Links

OCTOBER 15, 2024

RFID tags, GPS trackers, and integrated SCM software allow you to track your products from origin to destination. These systems can automate documentation and provide alerts when regulations change, ensuring that your business stays compliant. Non-compliance can result in delays, fines, and damage to your business’s reputation.

Logistics Bureau

JANUARY 20, 2025

Smart Inventory Management – Smart inventory systems use IoT sensors and RFID tags to monitor stock levels in real time. RFID and barcode scanning systems track every item movement in real time, no manual counting errors. These smart robots talk to the WMS to optimise picking routes and cut order fulfillment time in half.

Logistics Business Magazine

MAY 27, 2020

Experts from German RFID specialist Kathrein Solutions say yes: The global market is setting new standards for a more intelligent supply chain. A Stuttgart-based automotive manufacturer wanted to lead the way regarding digitisation and introduced RFID [1] as the basic infrastructure technology in its manufacturing plant.

Logistics Business Magazine

MARCH 24, 2022

Consistent documentation. In wine production, all processes must be fully documented. The grape containers are each equipped with four inconspicuously attached RFID sticker tags that are automatically read by the forklift when they are picked up. 8,000 RFID sticker tags (four for each of the 2,000 grape containers).

Material Handling and Logistics

DECEMBER 2, 2018

Customs and Border Protection (CBP) has implemented a new process to allow shippers to submit original vehicle export documentation electronically in lieu of delivering physical copies to their local CBP trade office. Content Summary: New Electronic Vehicle Export Process Debuts at Port Everglades. To save both time and money, U.S.

MTS Logistics

JUNE 9, 2023

Advanced tracking technologies, such as GPS, RFID, and real-time data analytics enable companies to monitor the movement of goods in real-time, ensuring transparency and reducing the risk of delays or losses.

GlobalTranz

OCTOBER 21, 2015

It can take months to negotiate a complex SLA/KPI document, as you go back and forth with your logistics provider so the document becomes a “win-win” for both parties. The more KPIs, the more difficult the negotiation process. 9 Key Topics to Understand to Frame A Shipper's Mind for Effective KPI Management.

GlobalTranz

AUGUST 11, 2017

Think of manual systems as Excel documents and endless spreadsheets. In addition, inventory management systems may include the use of automated identification and data capture ( AIDC ) technologies, including radio-frequency identification (RFID) chips. Active Versus Passive RFID Inventory Management Systems. Manual Systems.

GlobalTranz

APRIL 27, 2015

Although the technology, such as RFID chips , has reduced missing merchandise from the manufacturer, it still could be incorrect if the Radio Frequency Detectors on the chip were incorrectly assigned to the item(s). For consumers unable to provide such documentation, the claim will be considered invalid.

Trinity Logistics

JUNE 3, 2021

Keeping proper documentation of data throughout your supply chain can seem difficult but modern technology like a transportation management system (TMS) , can simplify this cold chain challenge. Some of these temperature monitoring systems are RFID or wireless sensor network, thermal imaging , and temperature loggers.

20Cube Logistics

OCTOBER 29, 2020

It enables the businesses to accurately predict the demand and also adjust routes for last mile deliveries as well as predict the nature and volume of material flow (for example, weather patterns, GPS and RFID) that affect the delivery time. Document invoices and payment requests. To know more on Chatbo t, click here.

Logistics Business Magazine

DECEMBER 2, 2019

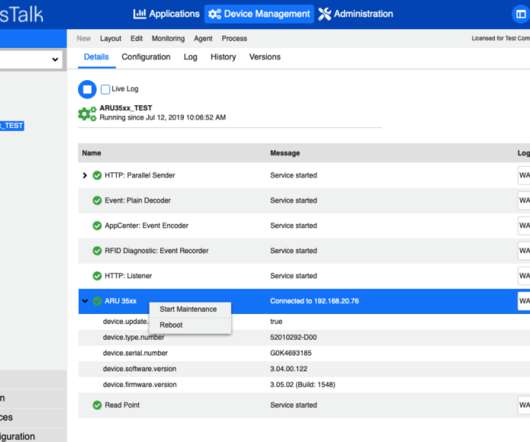

The software, which is widely used in RFID, AutoID and RTLS environments, has been enhanced with numerous new and improved functions. The robust and modular software integrates all common RFID devices and RTLS systems. Automated Documentation. In a press release the company said: With version 3.4,

Material Handling and Logistics

JANUARY 22, 2018

Then the file is recombined into a single document before being read by the receiving device. The latest findings indicate that the containers of tomorrow likely will be intelligent RFID-chipped ones that can be broken down into eight separate, different size modules that fit together like Lego blocks to form one 40-foot container. .

Logistics Business Magazine

JANUARY 25, 2021

They will have documented evidence of every barcode label printed and their grade at the time of printing. This industry leading capability is ideal for retail supply chain applications where vendors not only struggle with barcode quality but are also required to use RFID labels on their shipments.

Dedola Global Logistics

MAY 1, 2025

Blockchain Bill of Lading: A digital version of the traditional bill of lading document, using blockchain technology to securely record and transfer title and information about goods received for shipment, aiming to replicate the functions of its paper equivalent.

Dedola Global Logistics

APRIL 30, 2025

Blockchain Bill of Lading: A digital version of the traditional bill of lading document, using blockchain technology to securely record and transfer title and information about goods received for shipment, aiming to replicate the functions of its paper equivalent.

Logistics Bureau

JULY 18, 2022

As a result, and as we’ve mentioned in several previously published articles, we’ve discovered that many companies lack a defined and documented supply chain strategy. Will barcode tracking prove satisfactory for the needs of your new strategy, or will you need to upgrade to RFID? Include Your New KPIs in Your Strategy Document.

GlobalTranz

APRIL 3, 2018

Retailers can show consumers the historical lineage of the product’s path Digitize and secure travel document workflows on the blockchain Currently, an overwhelming amount of redundant paper-based documentation plagues importers, exporters, and intermediaries in the global transportation process.

Logistics Bureau

OCTOBER 6, 2024

COA Certificate of Analysis – A document that confirms a product meets its product specification. EDI Electronic Data Interchange – The computer-to-computer exchange of business documents in a standard electronic format between business partners. In logistics, RFID is used for inventory tracking and supply chain visibility.

Now, That's Logistics

AUGUST 3, 2018

A verification risk management capability, track-and-trace helps business partners, authorities, and ultimately consumers to manage and respond to risks—both potential risks and those that have already occurred—in a responsive and documented way. Put RFID, Bluetooth, and 3D printers to work.

Automotive Logistics

MAY 23, 2018

The Automotive Data-Ecosystem, which uses data gathered from RFID tags on the containers and digital platform provided by a digital supply chain and packaging specialist Surgere, was announced at The Supply Chain Conference in Atlanta, Georgia , this week as an answer to the industry-wide problem of poor management of returnable containers.

Blue Grace Logistics

DECEMBER 18, 2018

Digitalization, RFID tags, and GPS trackers have immensely improved shipment visibility. Now, with the new technology like the RFID tags and ERP systems warehousing operations have become much easier, less time consuming and more efficient. Now, documents pertaining to a shipment or sale can be stored in digital format on the system.

Logistics Business Magazine

OCTOBER 14, 2020

Antennas are positioned near the gates to autodetect RFID seals placed on containers and control entrances. ESeals have inside an RFID electronic component with a numbered sequence which allows immediate identification of each container. This helps avoid any possible delay caused by inspections.

PINC

OCTOBER 8, 2020

Combining powerful execution functionalities such as electronic documentation, analytics, billing, rating and carrier management with real-time visibility, the platform is well-positioned to solve multiple transportation challenges in the supply chain industry.

Blue Grace Logistics

JUNE 1, 2021

Single-use tracking devices and radio frequency identifiers (RFID) are also widely available now and can be used to track pallets thus making the cargo trackable in case of theft. This provides transparency and end-to-end visibility for all stakeholders while being virtually impossible to manipulate.

The Logistics Academy

JANUARY 23, 2017

Every time a product changes hands, the transaction could be documented, creating a permanent history of a product, from manufacture to sale. Tracking purchase orders, change orders, receipts, shipment notifications, or other trade-related documents. Linking physical goods to serial numbers, bar codes, digital tags like RFID, etc.

GlobalTranz

SEPTEMBER 27, 2018

Barcode, RFID and NFC labels and tags are more affordable than ever and can help you achieve peace of mind through asset tracking. Furnishing FAIR documents and completing other auditing processes is one way to make sure they don’t. Last Step: The Final Review The last thing on your agenda is the final review.

AAJ Enterprises

DECEMBER 12, 2017

Their IT capabilities are productive to track down the each and every consignment or delivery with the latest or advanced technology like AI, cloud-based platforms, IoT (Internet of things), RFID (Radio-frequency identification) and many more. Also, these services can benefit businesses in a lot of ways.

GlobalTranz

SEPTEMBER 2, 2016

But, if you accept damaged freight without documented each and every damaged item, you could be stuck with the bill in the end. Some carriers may have longer claim times, and newer technologies, such as RFIDs , may be used to prevent missing freight from being an issue. Don’t Carriers Automatically File Damaged Freight Claims?

PINC

SEPTEMBER 15, 2020

Combined with real-time visibility, electronic documentation, analytics, billing, rating and carrier management functionalities, the platform is well positioned to solve multiple transportation challenges in the supply chain industry.

Automotive Logistics

SEPTEMBER 11, 2018

Manufacturing at the Mercedes-Benz Vans plant includes driverless transport systems and paperless documentation. Autonomous transport vehicles, which can travel more than 60km in a shift, are controlled through the South Carolina plant’s IT system and the use of radio frequency identification (RFID) technology.

Logistics Bureau

MAY 24, 2019

The Path to Cost Reduction: Terex decided to replace the outdated manual yard management process with a new, digital solution using RFID tracking. Terex decided to replace the outdated manual yard management process with a new, digital solution using RFID tracking.

Logistics Business Magazine

NOVEMBER 10, 2023

Customers can view the location of the shipment and vehicle on a map via an individual tracking link; and following delivery, an electronic POD will also be made available in the documents section. The portal offers customers 24/7 access to documentation and the opportunity to access quotes and make bookings at any time, from any place.

Automotive Logistics

FEBRUARY 7, 2019

An initial test saw the wrinkles ironed out and documentation refined. On arrival at the plant, a check confirms whether the vehicle is expected or not, and the driver is handed an RFID tag. This printed documentation, says Dachs-Wiesinger, is now the only paper in the system. Enhanced visibility.

GlobalTranz

AUGUST 18, 2016

As a result, more companies are deploying radio frequency identification (RFID), Bluetooth monitoring and machine-to-machine connected devices to monitor and manage their shipments more accurately. However, stresses on today’s distributors are making carriers and shippers refocus their efforts to use the IoT.

20Cube Logistics

MAY 14, 2019

New technologies like RFID already starts helping in efficiency improvement and better safety in the supply chain processes. With our online platform “MyHub”, we provide end to end visibility, live inventory monitoring, vendor management, online documents, exceptions management and more. are also coming to India.

Logistics Bureau

OCTOBER 31, 2017

For example: Paperwork and data entry: WMS has reduced the need for people to spend time completing paper forms or entering data from documents into spreadsheets and other data-management applications. There are rows and rows of file boxes stored on pallets, presumably containing years of paper records and documents.

Logistics Business Magazine

OCTOBER 5, 2021

Visitors to the 73 exhibition booths had various ways to interact with the exhibitors, and the most popular documents had 200 downloads, whereas the most popular exhibitor video was watched 220 times. Running in tandem with the conference was the online exhibition, which drew 4,500 visits.

Expert insights. Personalized for you.

We have resent the email to

Are you sure you want to cancel your subscriptions?

Let's personalize your content