Ethical Considerations in Supply Chain Compliance

Logistics Viewpoints

JANUARY 15, 2025

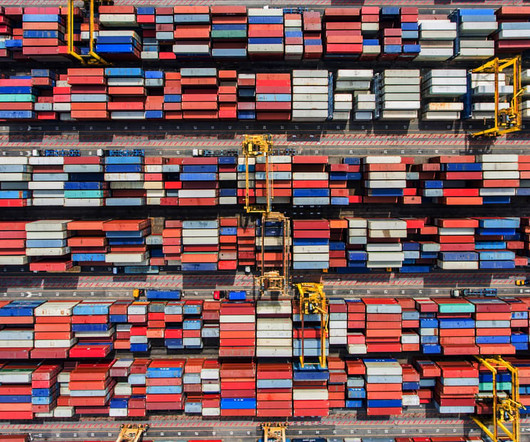

From balancing cost-efficiency with ethical sourcing to enhancing transparency and integrating corporate social responsibility (CSR), businesses face mounting pressure to align their operations with sustainability, technology, and energy practices. The energy sector provides a compelling example of CSR-driven compliance.

Let's personalize your content