Outsourcing transport and warehousing: How to be Successful

Logistics Bureau

DECEMBER 24, 2024

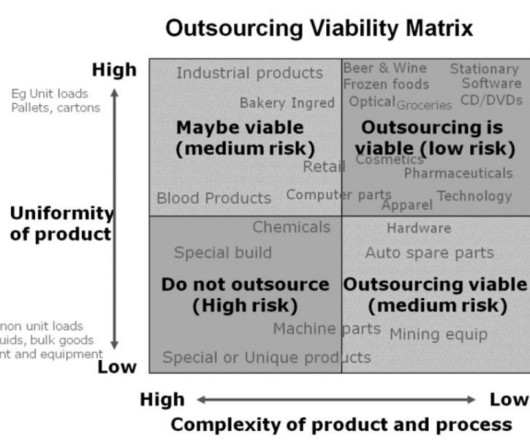

Peters and Waterman in their best, sellerIn Search for Excellence identify one of the eight factors of organisational success as sticking to the knitting. Reduction in asset capital.Warehouses and vehicles are expensive to purchase or lease and can tieupmillions of dollars that could otherwise be invested in the core business of the firm.

Let's personalize your content