Supply Chain Optimization: Leveraging Integrated Scenario Planning as a Margin Multiplier

Logistics Viewpoints

MAY 23, 2024

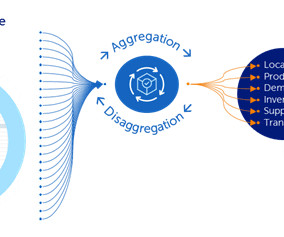

Situation Companies are increasingly confronted with complex planning scenarios due to predictable events such as mergers and acquisitions, category expansions, supplier changes, and distribution evolution, as well as disruptive events including demand volatility, material shortages, capacity constraints, and logistical surprises.

Let's personalize your content