A Trillion Dollars in Freight Transactions with Ken Adamo

The Logistics of Logistics

NOVEMBER 5, 2024

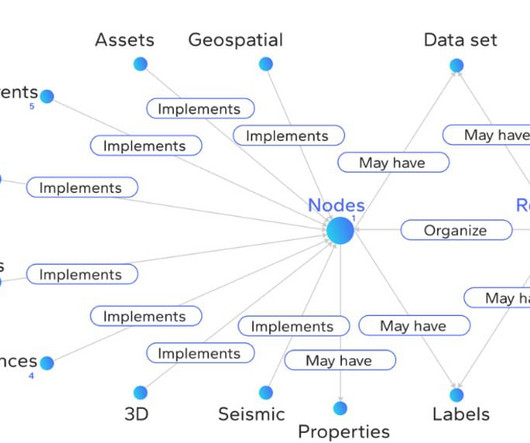

He leads a team of market experts who study every facet of the logistics industry to bring the best available insight to customers. During his tenure in the industry, he built innovative pricing and forecasting models, leveraging internal and external data sources to improve internal decision-making and increase profitability.

Let's personalize your content