Simplifying Data Management: How to Turn Raw Data into a Competitive Advantage

WorkWave

APRIL 15, 2025

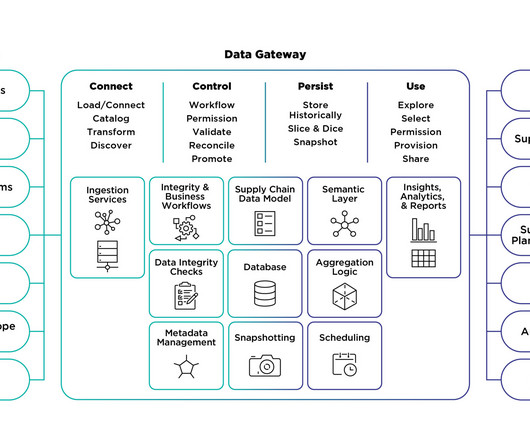

For example, Data Factory offers integrated solutions within the Wavelytics platform to truly make this a simplified business intelligence engine that outperforms manual analysis methods. The post Simplifying Data Management: How to Turn Raw Data into a Competitive Advantage appeared first on WorkWave.

Let's personalize your content