How to Reduce Carbon Footprint in Your Supply Chain

Logistics Bureau

DECEMBER 28, 2024

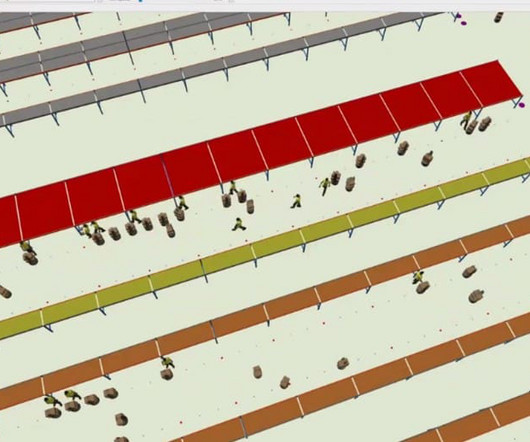

How to Reduce Carbon Emissions in Your Supply Chain 1. For example, switching from air to ocean freight for non-time sensitive shipments can reduce carbon emissions by up to 95% per unit shipped. The difficulty many businesses now face, is understanding where to start. Through network optimization.

Let's personalize your content