Ethical Considerations in Supply Chain Compliance

Logistics Viewpoints

JANUARY 15, 2025

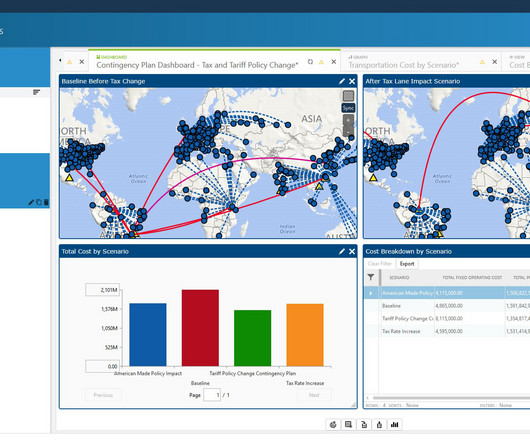

For example, integrating renewable energy into supply chains can reduce environmental footprints while enhancing brand equity, demonstrating a commitment to sustainable operations. Key transparency initiatives include: Supply Chain Mapping: Using digital tools to trace the journey of products from raw materials to finished goods.

Let's personalize your content