How Automated Guided Vehicles Transform Material Handling

Conger

MARCH 22, 2024

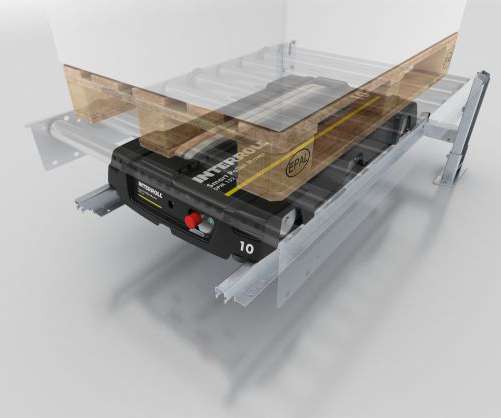

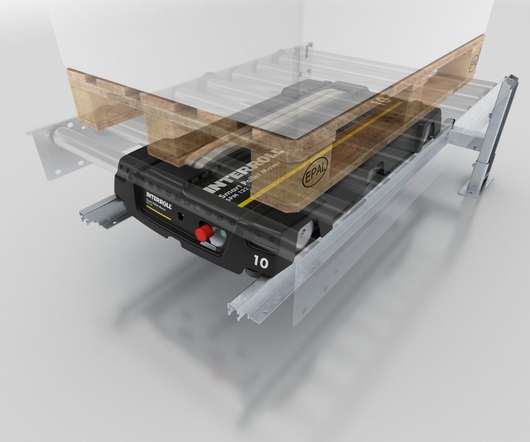

The Role of AGVs in Improving Safety Automated Guided Vehicles are revolutionizing material handling across various industries. By automating routine or hazardous material handling tasks, AGVs significantly reduce the risk of workplace accidents often seen in manufacturing facilities.

Let's personalize your content