Supplier Onboarding is Core to a Digital Supply Chain Transformation

Logistics Viewpoints

JANUARY 6, 2025

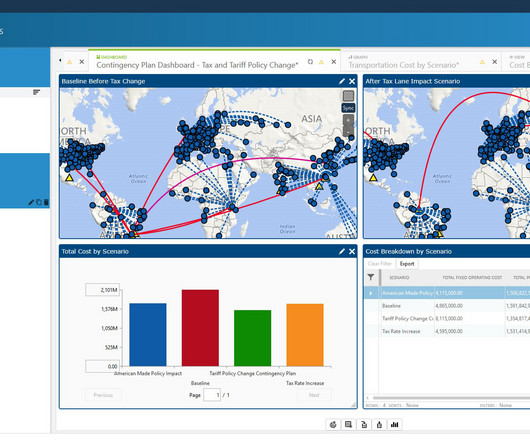

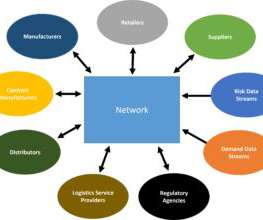

Molex implemented a multi-enterprise supply chain network platform from SAP called SAP Business Network. With PO collaboration, buyers send digital purchase orders over the network to suppliers or other trading partners. The task management in SAP Business Network also helps. But getting there was not easy.

Let's personalize your content