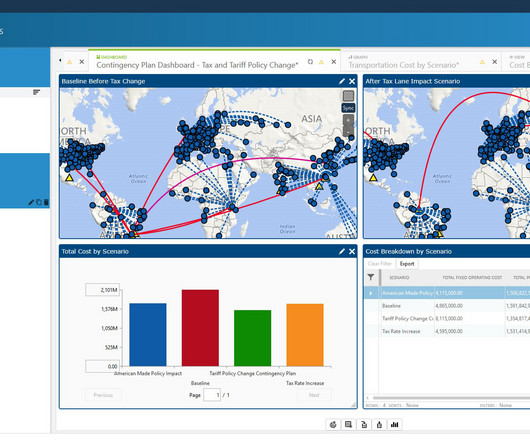

Last Mile Delivery Optimization Strategies for 2025

WorkWave

DECEMBER 2, 2024

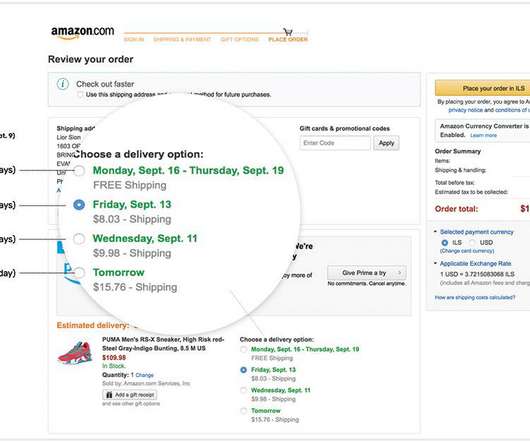

As customers increasingly demand rapid and reliable delivery, optimizing this final leg of transportation becomes essential for businesses aiming to enhance customer satisfaction and operational efficiency. Key Benefits of Last-Mile Delivery Optimization: Reduction in operational costs and fuel consumption.

Let's personalize your content