Developing Agile Procurement Strategies: Thriving Amid Global Trade Disruptions

Logistics Viewpoints

MARCH 6, 2025

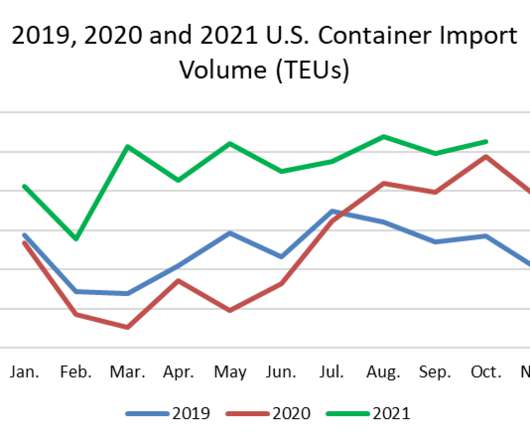

manufacturer I know saw their import costs jump overnight, forcing a rethink of a decade-old sourcing strategy. Traditional procurement, with its long-term contracts and rigid supplier ties, just isnt cutting it anymore. They may be able to shave 15% off their costs and dodge a tariff bullet. What Is Agile Procurement?

Let's personalize your content