Breaking Data Silos: How Centralized Data Warehouse Transforms Multi-Branch Operations

WorkWave

MARCH 5, 2025

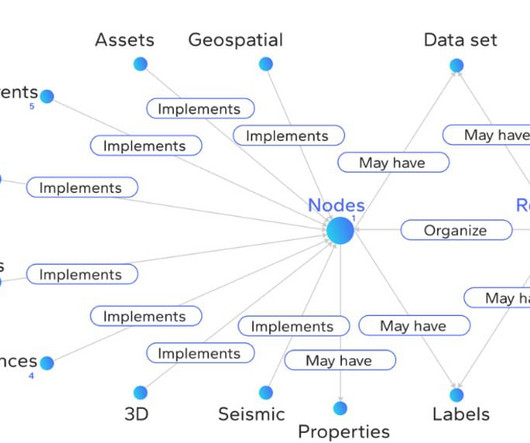

By seamlessly integrating data from multiple sources across branches and business functions, organizations can eliminate data silos , ensure consistent and reliable information, and gain real-time visibility into operations. Delayed decision-making: Teams waste time manually gathering and cleaning data.

Let's personalize your content