No More Black Swans: The Age of Supply Chain Uncertainty

Freightos

APRIL 29, 2025

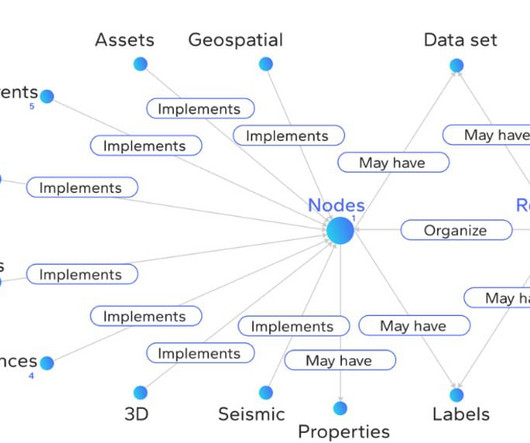

Home No More Black Swans: The Age of Supply Chain Uncertainty Freightos Enterprise unifies market intelligence, tender management, and shipment operations into one solution, enhancing logistics efficiency for large import-export businesses. The Problem with Fragmented Solutions The logistics technology space is undeniably crowded.

Let's personalize your content