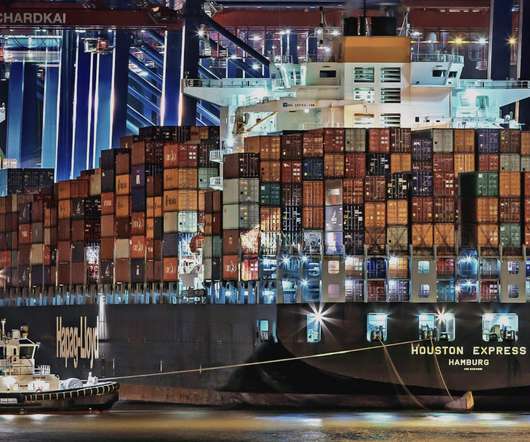

How to Make Your Supply Chain More Resilient

Logistics Bureau

JANUARY 16, 2025

Think of it as your supply chain’s immune system. The resilience of your supply chain is determined by its structure and operations, whether we’re dealing with major immediate events like a pandemic or gradual systemic changes to your business environment over time.

Let's personalize your content