Unlocking Supply Chain Potential with AI Agents and Multi-Agent Workflows

Logistics Viewpoints

JANUARY 21, 2025

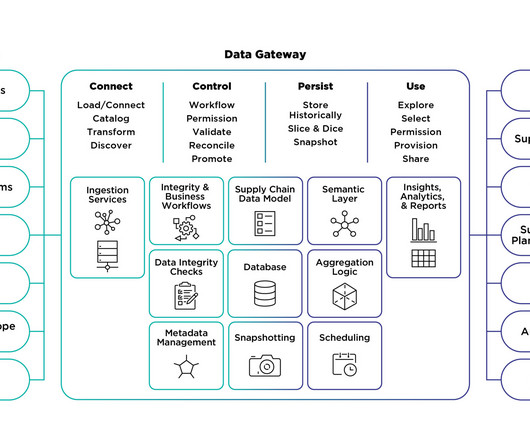

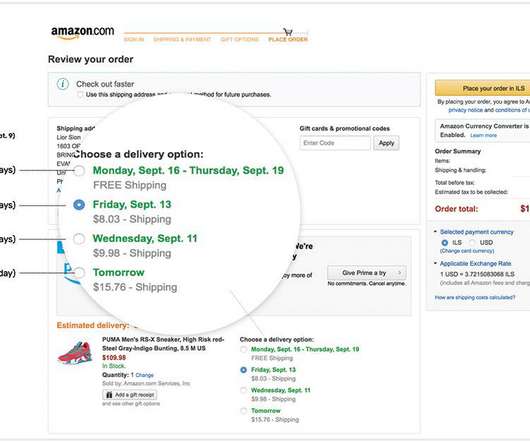

The industrial sectorparticularly supply chain management, is facing unprecedented complexity. Volatile markets, global disruptions, and the need for real-time insights are pushing traditional systems to their limits. Typically, these systems consist of standard-task agents (e.g.,

Let's personalize your content