OneRail’s Winning Strategy for Final Mile with Bill Catania

The Logistics of Logistics

JANUARY 7, 2025

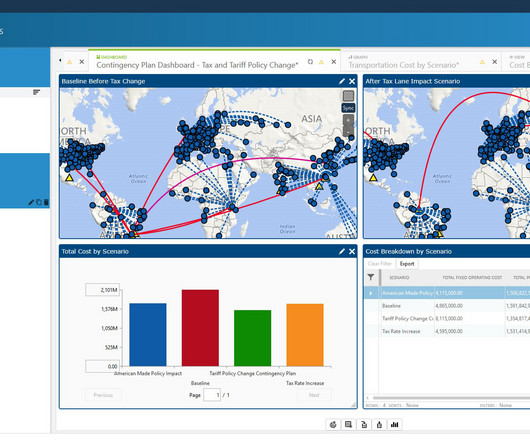

With its recent acquisition of Orderbot, a distributed order management solution, OneRail is integrating inventory and order management capabilities to enable store-shelf-to-doorstep visibility. OneRail’s platform includes order management, inventory management, and real-time visibility.

Let's personalize your content