Supply Chain & Logistics News December 2nd- December 5th

Logistics Viewpoints

DECEMBER 6, 2024

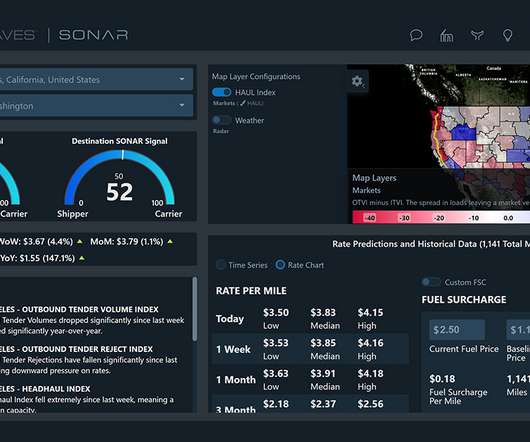

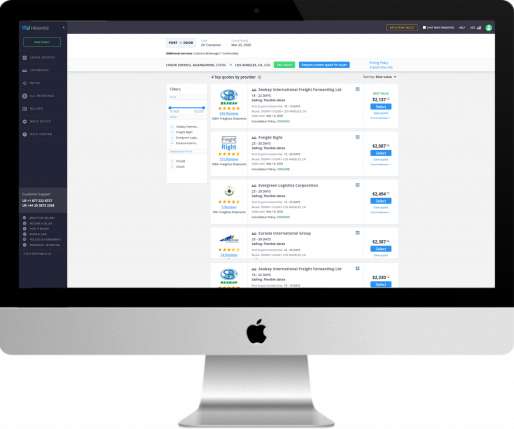

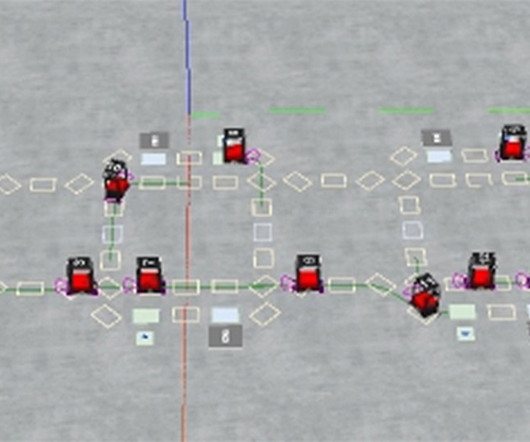

Supply Chain & Logistics News December 2nd – December 5th Experts claim that Cyber Monday the Monday following Thanksgiving is one of the busiest days for deliveries followed by the Mondays leading up to Christmas. Companies will become increasingly dependent on digital tools to sort, track, and mitigate issues at the border.

Let's personalize your content