Automated Material Handling: Systems, Solutions, and Industry Applications

Conger

JANUARY 29, 2025

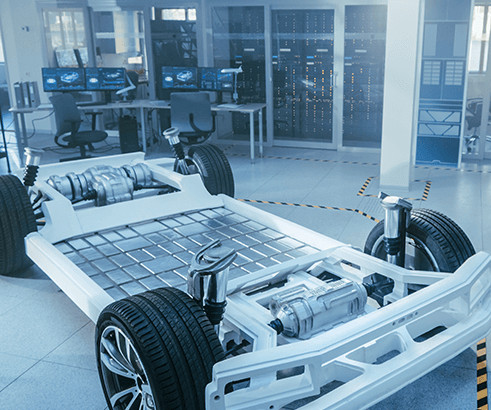

Automated material handling (AMH) is transforming logistics, warehousing, and manufacturing. Businesses are replacing manual processes with automated material handling systems to improve efficiency, reduce costs, and enhance accuracy. What Is an Automated Material Handling System?

Let's personalize your content