How Data-Driven Maintenance Transforms Materials Handling

Logistics Business Magazine

OCTOBER 24, 2024

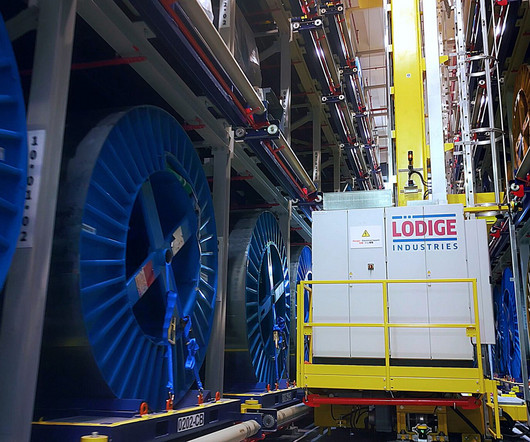

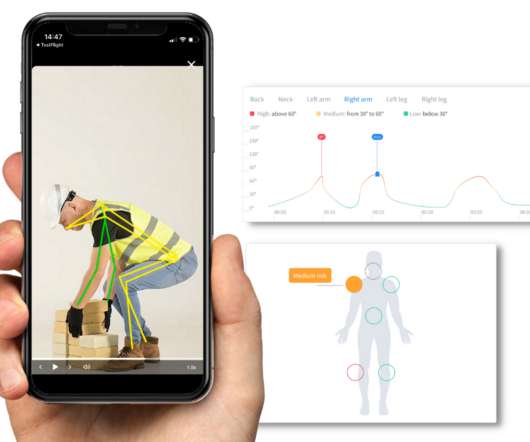

Current materials handling and intralogistics equipment is amazingly reliable. All the sites we instal have this data waiting to be used and we have the software tools capable of analysing this data, to inform our decisions on the most appropriate, proportionate actions to take. None of this is good for sustainability.

Let's personalize your content