AI in Supply Chain Automation: Procurement to Logistics

Logistics Viewpoints

APRIL 14, 2025

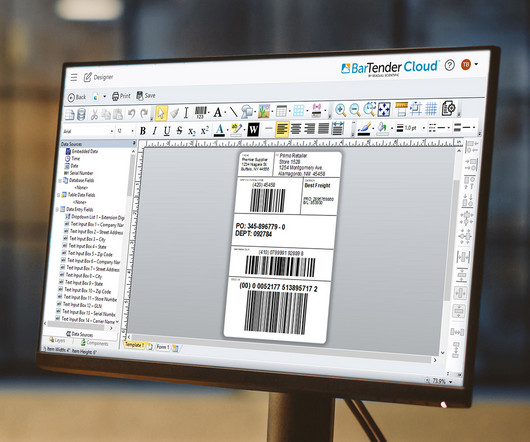

Outcomes: Higher order accuracy and improved on-time performance Lower labor cost per unit moved and less reliance on overtime Reduced downtime due to more proactive equipment servicing Many of these tools depend on inputs from sensors such as RFID tags, barcode scans, and environmental monitors.

Let's personalize your content